When it comes to pipeline integrity, coating is one of the most important factors to consider. Preventing oxidization is crucial and Canusa coating are the best way to do that. Whether it’s sleeves, epoxy, or directional drilling coating Canusa has you covered with their diverse coating lineup.

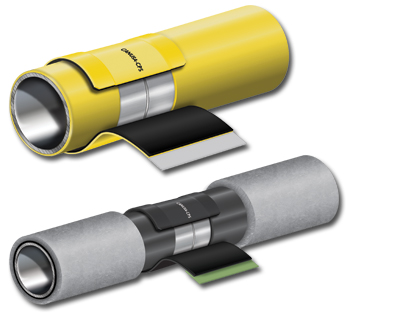

K-60 sleeves

The Canusa K-60 wraparound sleeve is designed for corrosion protection of buried and exposed steel pipelines operating up to 60 C (140°°F). K-60 consists of a crosslinked polyolefin backing, coated with a technologically advanced corrosion protective adhesive, which effectively bonds to steel substrates and common pipeline coatings including polyethylene and fusion bonded epoxy.

Canusa HBE-95

Canusa HBE-95 is an advanced two-component epoxy coating system which has been specifically formulated for pipelines worldwide. Applied to bare steel, HBE-95 has proven to withstand operating temperatures up to 95°C (302°F) with superior performance. HBE-95 is used for protection of pipeline field joint girth welds, valves, and fittings, as a holiday repair material on FBE coated pipe or for pipeline coating rehabilitation projects. This environmentally friendly, 100% solids, novolac epoxy system can either be spray applied or brush applied to the intended substrate.

TBK60/80’s

The TBK Directional Drilling system is specifically designed to protect welded joints on PE, FBE and HPCC coated pipelines in directional drilling applications. In addition to providing effective protection against pull-through forces that occur during the directional drilling operation, Canusa’s TBK systems provide superior corrosion protection at pipeline weld joints. The product range includes TBK-60, TBK-80 and TBK-PE, which are each designed to meet specific application conditions and operating requirements.

Scar-Guard

Scar-Guard® provides superior mechanical protection to field joint coatings on directionally drilled pipelines or areas where severe backfill conditions are present. Moisture curable polyurethane impregnated fiberglass protection system for joint coating, the Scar-Guard® provides effective protection against abrasion and wear forces that occur during the pull-through or backfilling operations.

Ready to get started? Contact us today to learn more about how Proline’s products and services can benefit your next project.