TBK-PE

The Canusa Wrapid Sleeve™ Type TBK-PE is a wraparound sleeve designed for corrosion protection of buried and exposed steel pipelines operating up to 100 C (212 F)

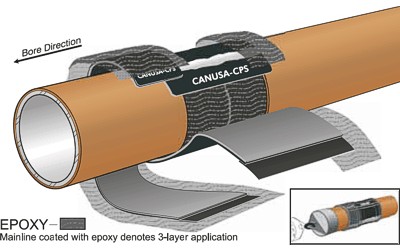

El sistema de perforación direccional TBK está diseñado específicamente para proteger las juntas soldadas en tuberías revestidas de PE, FBE y HPCC en aplicaciones de perforación direccional.

Además de proporcionar una protección eficaz contra las fuerzas de arrastre que se producen durante la operación de perforación direccional, los sistemas TBK de Canusa ofrecen una protección superior contra la corrosión en las juntas de soldadura de las tuberías.

Protección multicapa

• Force-cured liquid epoxy applied to steel, if required, for maximum corrosion protection

• Primary sleeve composed of high shear strength adhesive, a protective heat shrinkable backing, and a pre-attached

closure patch

• Sacrificial sleeve incorporated to protect the leading edge of the underlying primary sleeve during pull-through operation

• Epoxy overcoat applied at the leading and trailing ends of the joint coating to provide additional protection to the system during directional drilling

Resistencia superior al desportillado y la abrasión

• Designed to mitigate the effect of forces associated with directional drilling

• Highly resistant to the effect of soil stresses and pipe movements

• Canusa’s ScarGuard®, WrapidShield XLE and HBE-DX products are provided as alternatives for added mechanical protection as an overcoat

Tecnología adhesiva exclusiva

• Allows for lower installation pre-heat temperatures and superior bonding to mainline coating

• Adhesive has been formulated to bond directly to the mainline coating; epoxy (if required) is applied to the steel only

• Lower pre-heat temperature means less time heating resulting in application time and cost