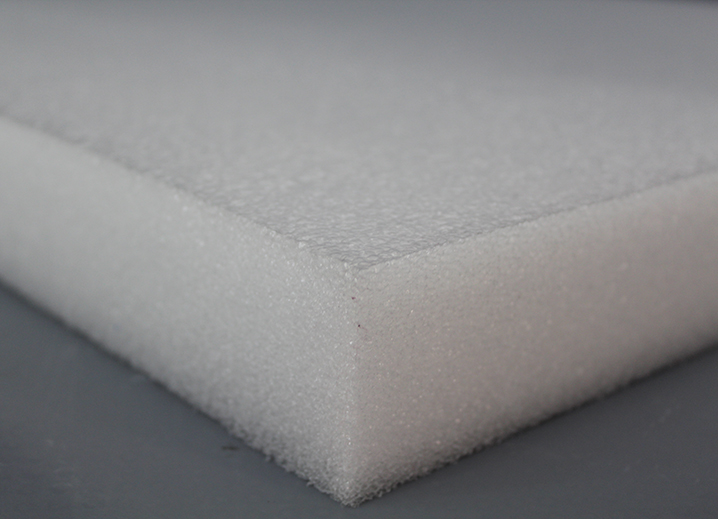

Ethafoam Protection

Ethafoam pipe protection is a high-performance solution designed to safeguard pipelines from damage in harsh environmental and backfill conditions. Its lightweight, flexible composition allows for easy installation, even in cold temperatures, without cracking or losing integrity.

Ethafoam pipe protection is the trusted choice for pipeline integrity in challenging conditions. Ensure your pipes remain secure and damage-free with this proven solution.

- Superior Protection – Shields pipe coatings from scrapes, dents, and punctures, reducing the risk of corrosion and mechanical damage.

- Chemical & Hydrocarbon Resistance – Withstands exposure to crude oil, bitumen, LNG, and a variety of chemicals without degradation.

- Durable & Long-Lasting – Will not rot, biodegrade, or attract insects, vermin, or mold, ensuring long-term reliability.

- Extreme Temperature Performance – Functions effectively across a wide temperature range, making it ideal for cold-weather installations.

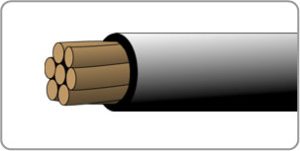

- Buried Hydrocarbon Drain Piping – Protects insulated, high-temperature pipes from soil pressure.

- Buried Vessels & Nozzle Connections – Prevents deformation and reduces stress on nozzles and tie-ins.

- Directional Bends & Riser Transitions – Supports unrestrained pipes as they change direction or exit the ground.