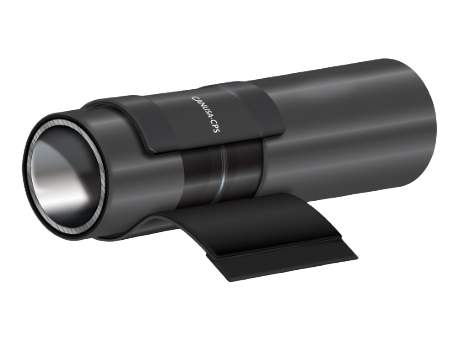

GTS-65

GTS-65 has been designed with a unique adhesive technology that remains “open” longer than traditional adhesives. Also, special surface active agents allow bonding to lower surface energy coatings (such as polypropylene). As a result, lower preheat temperatures are required to attain true adhesive wet-out and superior bonding to PE, PP and FBE surfaces is achieved.

GTS-65-EN can be used in conjunction with Canusa-CPS’s Liquid Epoxy Type E-WF or as 2-layer coating without liquid epoxy (Please refer to dedicated Installation Guide for more information).

Superior Force Cured Epoxy

- Proven method of force curing the liquid epoxy to the steel allows the installer to “pre-inspect” the joint prior to sleeve application.

- Force cured epoxy cannot be displaced during the aligning and shrinking stages of the sleeve installation.

Unique Adhesive Technology

- Allows for lower installation pre-heat temperatures and superior bonding to PE, PP and FBE coatings.

- Adhesive has been formulated to bond directly to the main line coating; epoxy is applied to the steel only.

Flexible Installation

- GTS-65 can be used as either a 2-layer or 3-layer sleeve system with the same low pre-heat temperature.

- For added flexibility, the sleeve can be supplied as bulk rolls or pre-cut to the required pipe size.

Long Term Corrosion Protection

- Provides a protective coating with the structural integrity of a seamless tube, providing excellent resistance to cathodic disbondment and excellent durability against abrasion and chemical attack

Saves Time & Money

- Lower pre-heat means less time heating