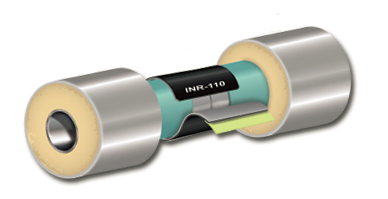

INR-110

INR-110 are heat shrinkable sleeves paired into a system which provides continuation of corrosion protection and foam sealing across pre-insulated pipeline joint.

INR-110 sleeve is applied directly onto the carrier pipe and has been designed to withstand conditions associated with the joint foaming operation, while maintaining its full set of anti-corrosion properties. Complementary, K-60 sleeve provides superior mechanical and sealing properties required to protect the foam during construction and pipeline operating conditions.

INR-110 sleeves are specifically engineered for use in combination with polyurethane half shells or other infill systems.

These sleeves are resistant to the conditions associated with the polyurethane foaming operation and maintain their full set

of anti-corrosion properties. INR-110 sleeves are fully compatible with a wide range of pipeline coatings, including PP, FBE, PE, Coal Tar and Tape.

Features and Benefits

Operator Friendliness – One-piece, wraparound sleeves with a factory bonded closures and a specially engineered product thickness results in optimum installation time. Single wrap configuration eliminates the requirements for muiltiple wrappings.

Crosslinked Polyolefin Backing – Proprietary crosslinking technology provides superior resistance to PUR in-fill while ensuring longterm hoop stress.

Unique adhesive technology allows for allow surface preparation requirement while ensuring long-term adhesion and excellent cathodic disbondment resistance properties.