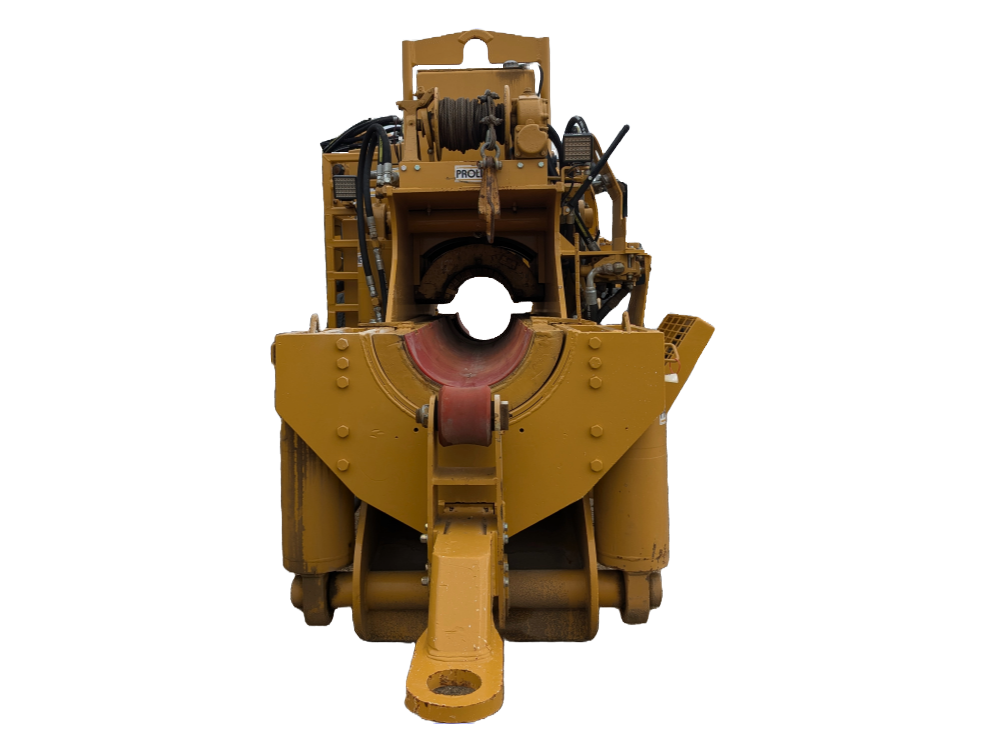

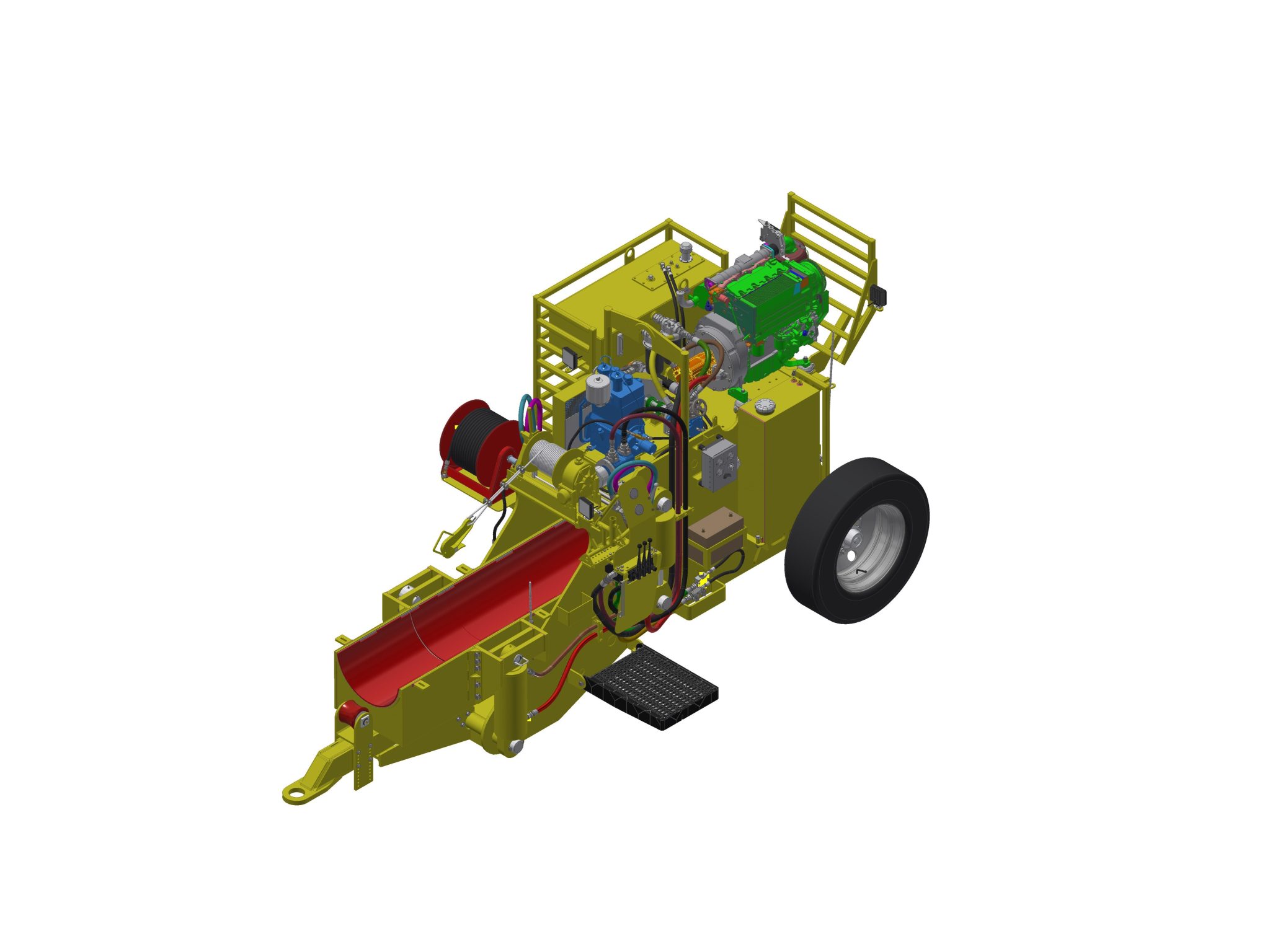

Pipe Bending Machine Model BM04-20

The Proline Pipe Bending Machine Model BM04-20 is a versatile and powerful tool designed for precision bending of pipes ranging from NPS 4 to NPS 20. Available in two robust configurations—Standard and Heavy Duty—this machine meets the demands of various industrial applications.

Both configurations are engineered for durability and efficiency, ensuring reliable performance even under heavy workloads. The BM04-20 is also equipped with two pneumatic tires, making it easy to transport and maneuver on job sites, offering convenience without compromising on capability.

BM04-20 Standard Model Specifications

Working Temperature: -49°F to 122°F / -45°C to 50°C

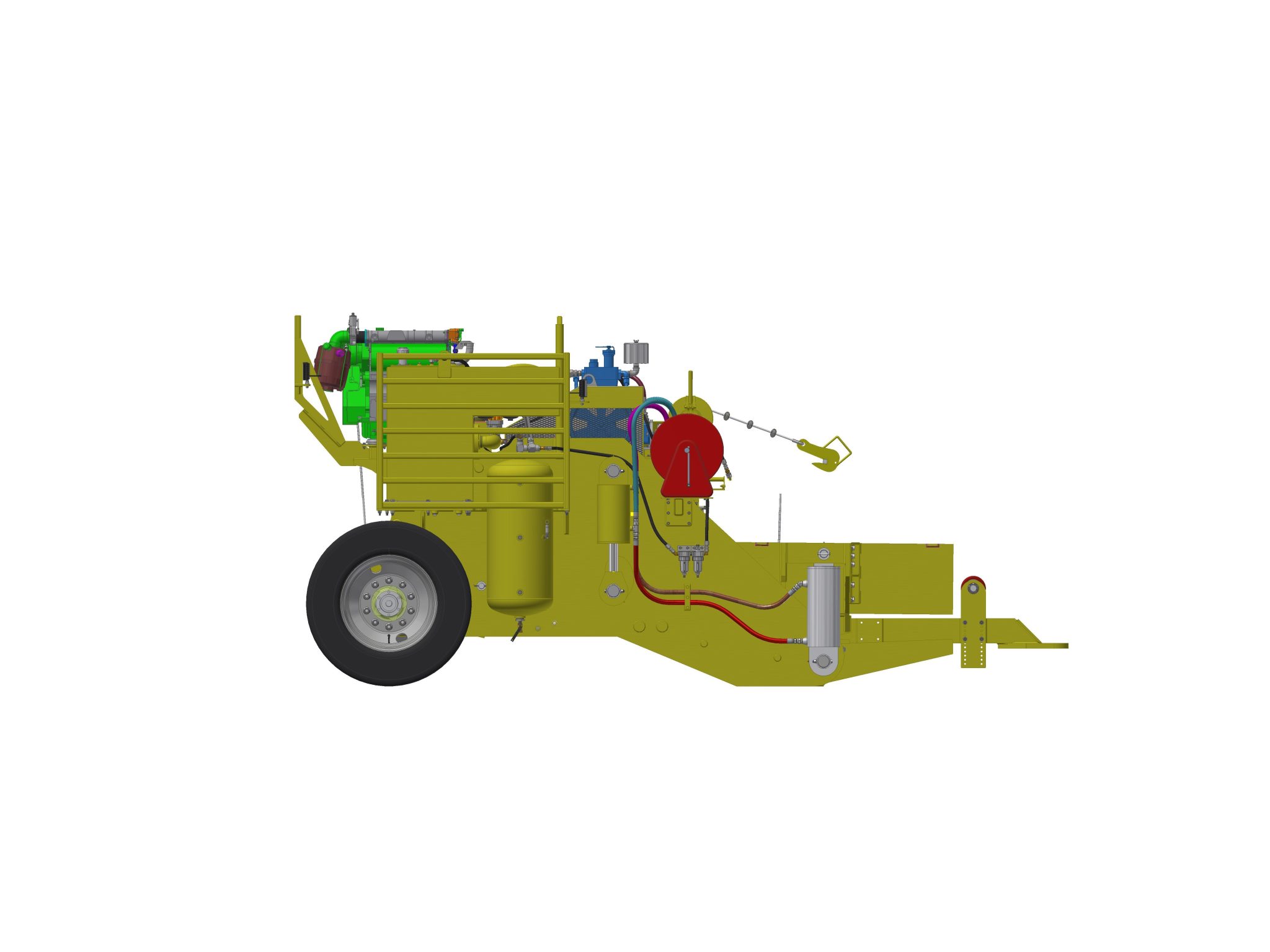

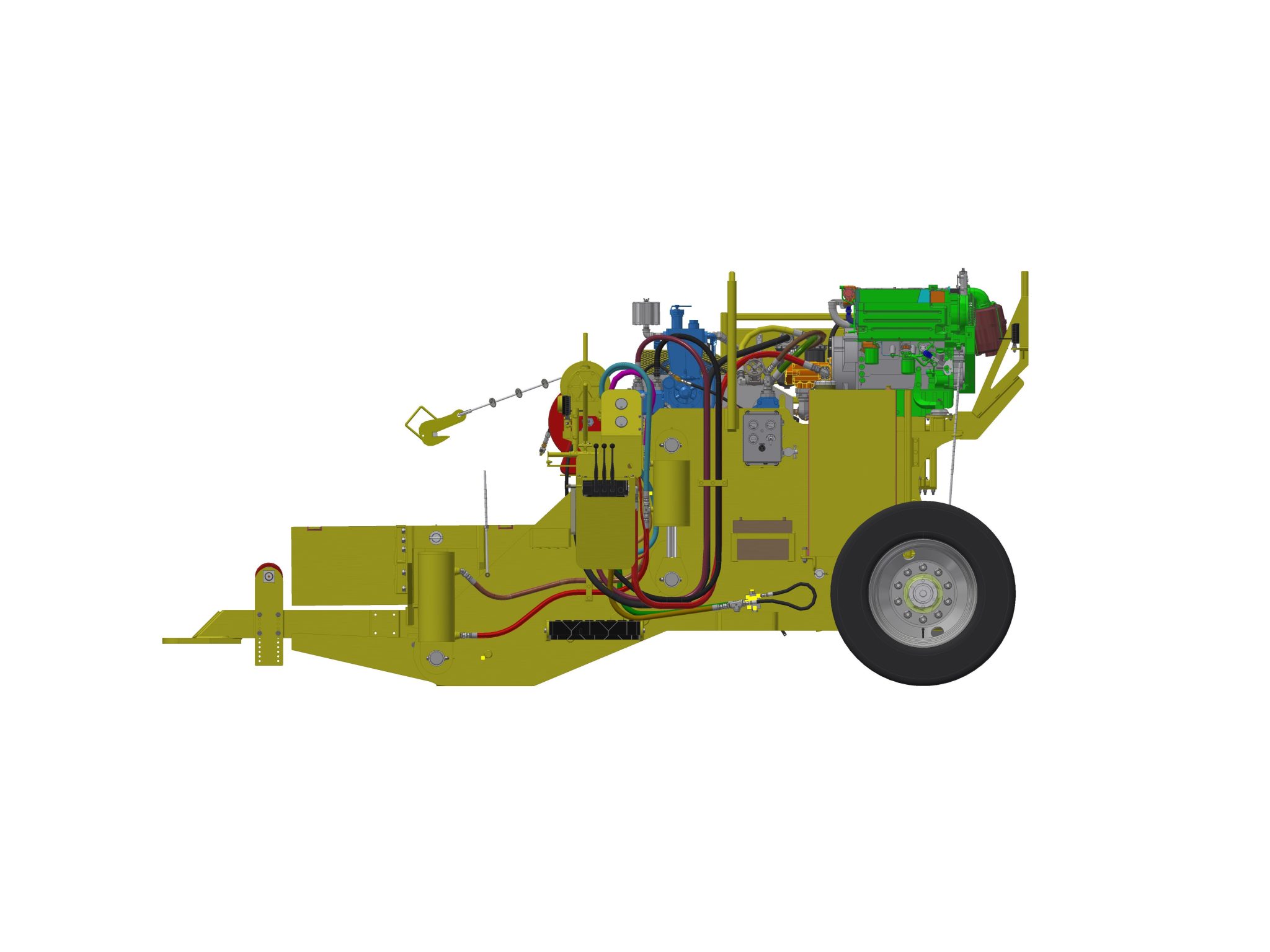

Undercarriage: Two Pneumatic Tires 11″ x 22.5″

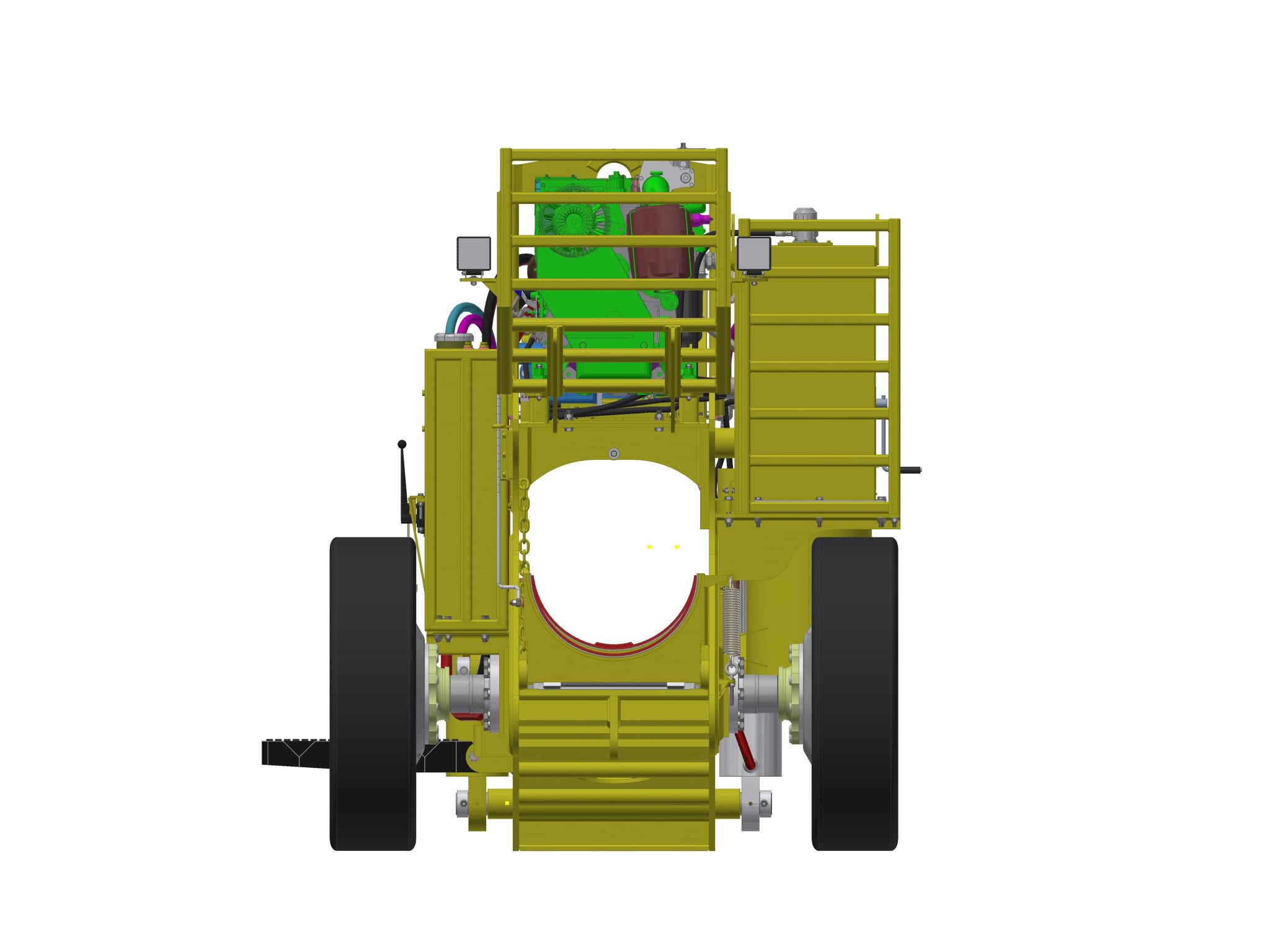

Engine Model Type: Deutz F3L 2011air cooled Diesel

Power: 48 HP/35.8 kW @ 2,800 rpm

Electrical System: 12 Volt Electric Start

Maintenance Free Battery: Yes

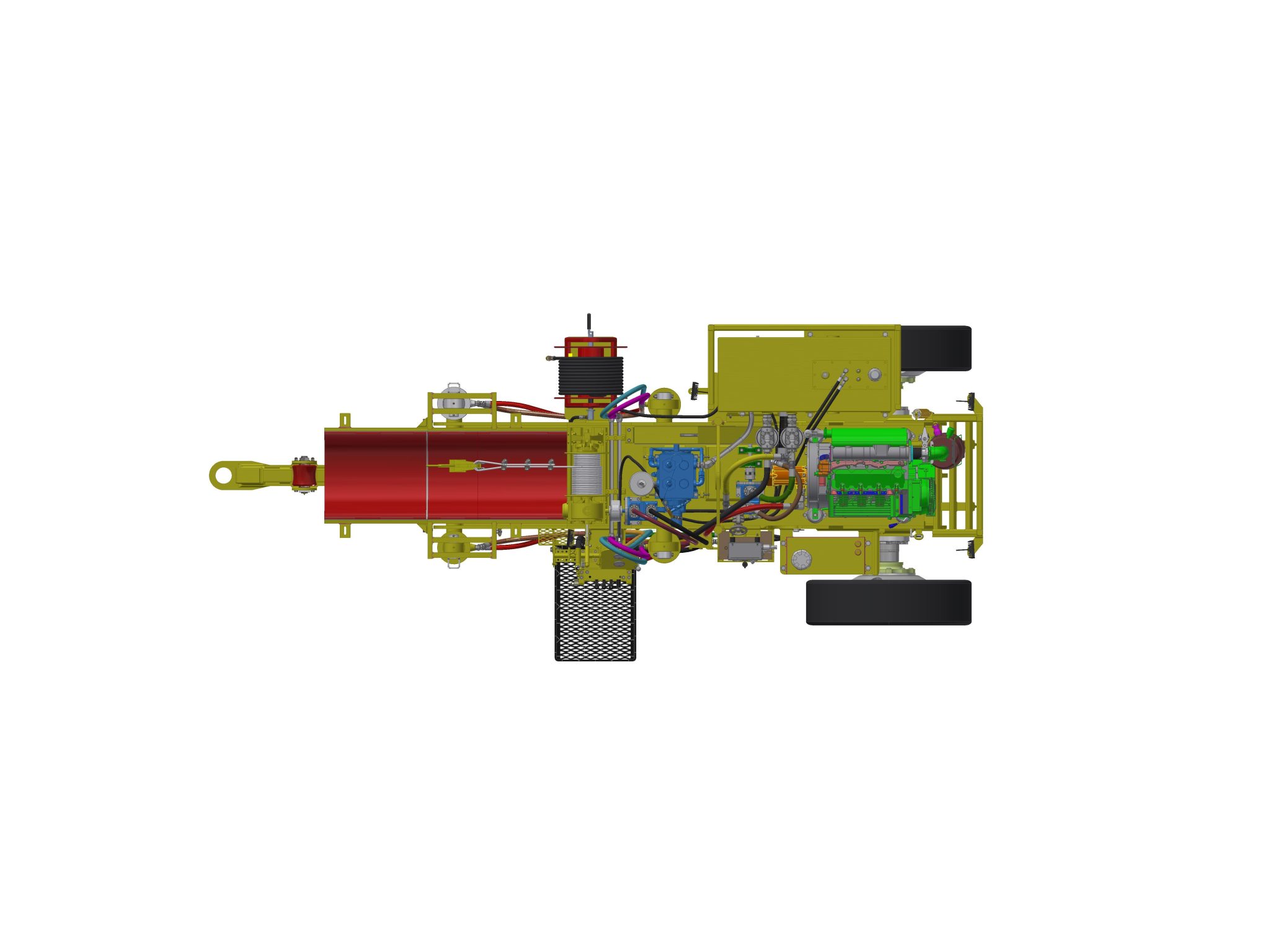

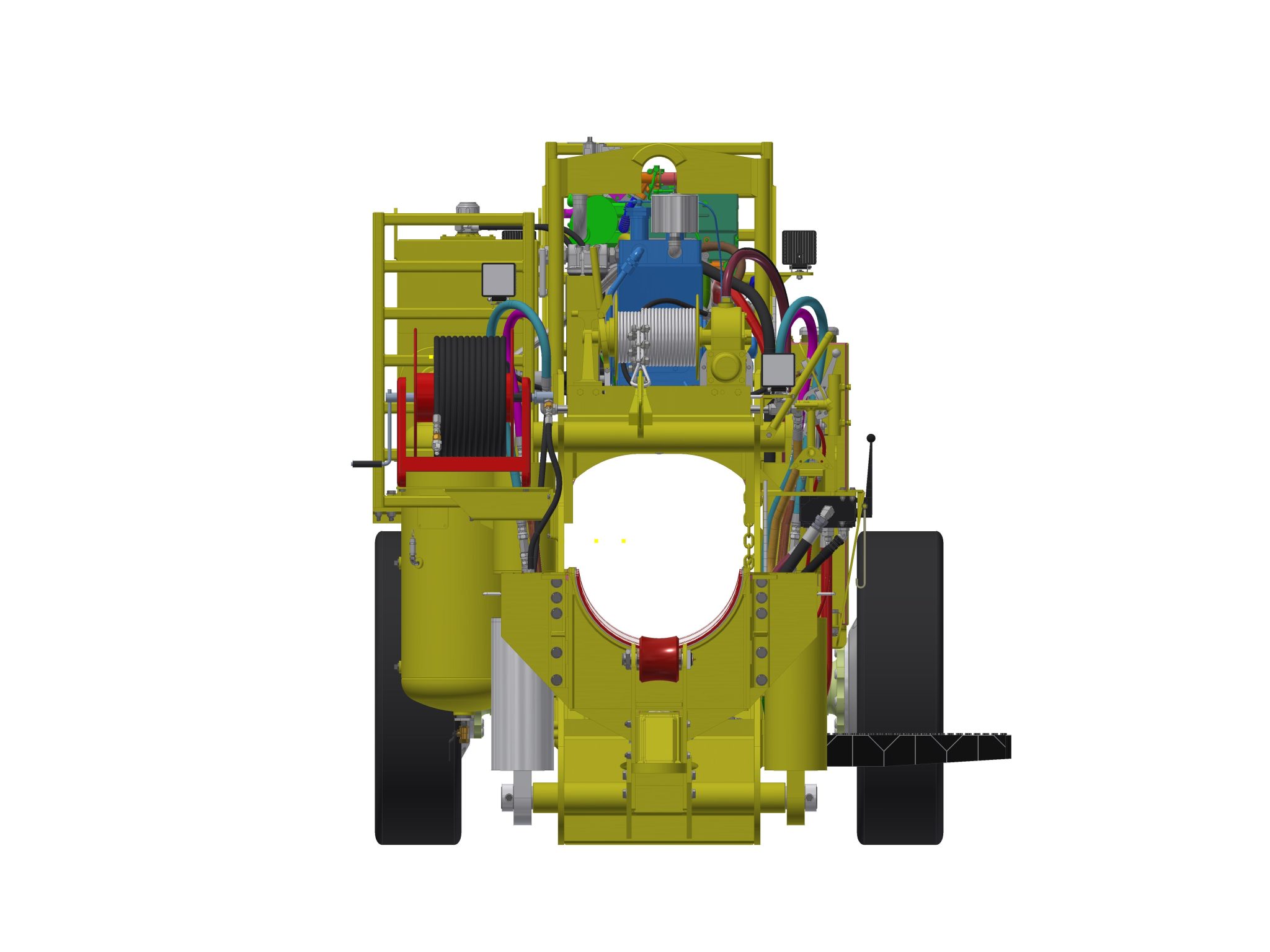

Hydraulic System

Maximum Operating Pressure: 2,500 psi

Pump: Vickers 2520 VQ Hydraulic Vane Drive

Flow at 2100 RPM: 31 US Gallons per Min / 116 Liters per Min

Outboard Cylinders: Two 7″ x 11″

Inboard Cylinders: Two 7″ x 5¾”

Hydraulic Drive Winch: Braden

Line Pull: 10,000 lbs / 4,540 kg

Length of Cable: 100 feet / 30.5 meters

Diameter of Cable:7/16 inch / 11.1 mm

Compressor: No

Length: 13 feet 4 inches / 4.06 meters

Width: 6 feet 2 inches / 1.87 meters

Height: 8 feet / 2.43 meters

Weight: 10,000 lbs / 4,540 kg

BM04-20 Heavy-Duty Model Specifications

Working Temperature: -49°F to 122°F / -45°C to 50°C

Undercarriage: Two Pneumatic Tires 11″ x 22.5″

Engine Model Type: Deutz F3L 914 air cooled Diesel

Power: 59 HP/44 kW @ 2,500 rpm

Electrical System: 12 Volt Electric Start

Maintenance Free Battery: Yes

Hydraulic System

Maximum Operating Pressure: 2,500 psi

Pump: Vickers 2520 VQ Hydraulic Vane Drive

Flow at 2100 RPM: 31 US Gallons per Min / 116 Liters per Min

Outboard Cylinders: Two 7″ x 11″

Inboard Cylinders: Two 7″ x 5¾”

Hydraulic Drive Winch: Braden

Line Pull: 10,000 lbs / 4,540 kg

Length of Cable: 100 feet / 30.5 meters

Diameter of Cable:7/16 inch / 11.1 mm

Compressor Model: Quincy QR25-325

Power at 175 psi: 3-5HP / 2.2 – 3.7 kW

Maximum RPM: 900

Flow at 175 psi: 18.64 CFM/FAD

Air Tank Capacity: 30 US gallon / 115 litre

Length: 13 feet 4 inches / 4.70 meters

Width: 6 feet 2 inches / 1.88 meters

Height: 8 feet / 2.44 meters

Weight: 13,200 lbs / 5,987 kg