Understanding Pipeline Pigging

Pipeline pigging is an essential process in the oil and gas industry, ensuring the integrity, efficiency, and longevity of pipelines. Pigging equipment is used to clean, inspect, and maintain pipelines without interrupting the flow of product. Whether for crude oil, natural gas, or water pipelines, the pigging process helps prevent blockages, corrosion, and inefficiencies.

What Are Pipeline Pigs?

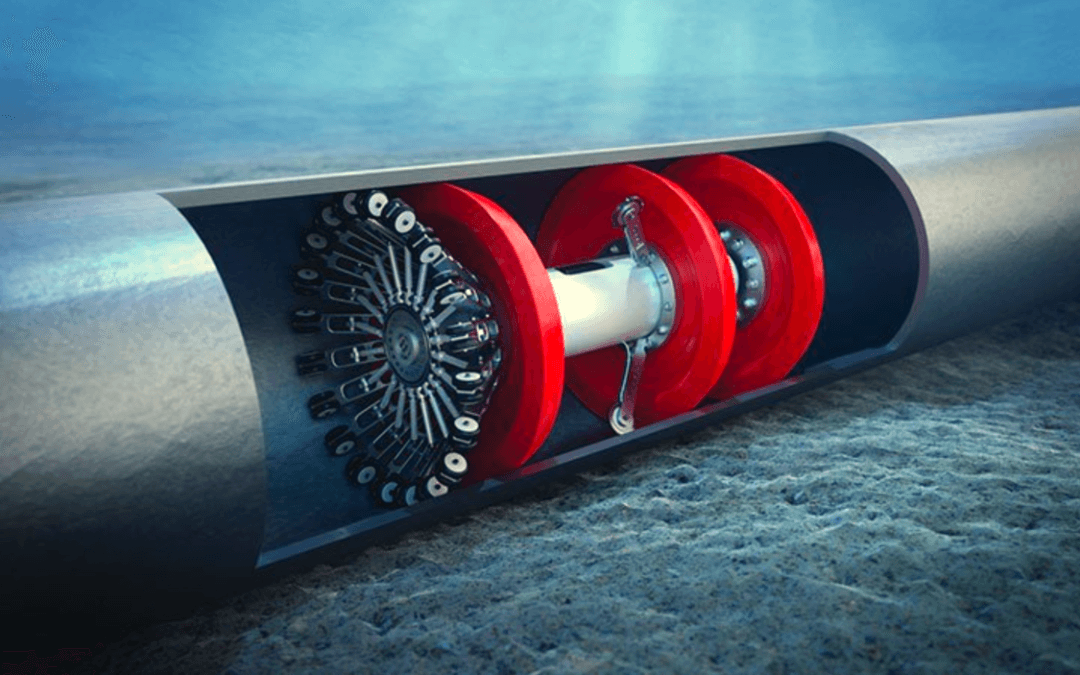

Pipeline pigs are devices inserted into pipelines to perform various maintenance tasks. They travel through the pipeline, pushed by the product flow or an external force, to remove debris, detect damage, and improve operational efficiency. Different types of pigs serve unique purposes, from cleaning to inspection and dewatering.

Types of Pipeline Pigs

- Utility Pigs – Designed for basic cleaning, these pigs remove loose debris, water, and deposits that can cause flow restrictions.

- Cleaning Pigs – Equipped with brushes, scrapers, or abrasive elements, cleaning pigs remove scale, wax, and corrosion byproducts from pipeline walls.

- Intelligent Pigs – Also known as smart pigs, these devices use advanced technology like magnetic flux leakage (MFL) or ultrasonic testing to inspect pipelines for corrosion, cracks, and other integrity issues.

- Gel Pigs – Used in special applications where solid pigs may not be suitable, gel pigs conform to the shape of the pipeline to remove contaminants effectively.

- Foam Pigs – Lightweight and flexible, foam pigs are ideal for removing liquids and light debris in pipelines of varying diameters.

- Scraper Pigs – Built with strong metal components, scraper pigs effectively remove stubborn deposits and ensure a clean pipeline interior.

The Pigging Process

The pigging process starts with the insertion of a pig into the pipeline through a pig launcher. The pig then travels through the pipeline, performing its designated task before being removed at the pig receiver. This process can be used for:

- Pipeline cleaning to remove dirt, scale, and buildup.

- Pipeline integrity inspection using smart pigging technology.

- Pipeline debris removal to maintain consistent flow and prevent blockages.

- Hydrostatic testing pigs to ensure pipeline strength and leak prevention.

- De-watering pigs to clear out moisture before introducing a new product.

- Drying pigs to eliminate residual water before final commissioning.

Benefits of Pigging Systems

Utilizing a pigging system offers several benefits:

- Enhanced Pipeline Integrity – Regular pigging prevents corrosion and identifies structural weaknesses before they become critical.

- Reduced Downtime – Pigging allows for maintenance without shutting down operations.

- Cost Savings – Preventative maintenance through pigging reduces costly repairs and unexpected failures.

- Environmental Safety – Reducing pipeline leaks and failures helps prevent environmental contamination.

Pig Launchers and Receivers

Pig launchers and receivers are essential components of a pigging system. These devices safely introduce and remove pigs from the pipeline without disrupting operations. A well-designed pig launcher ensures smooth insertion, while a pig receiver collects the pig once it has completed its journey.

Innovations in Smart Pigging Technology

Smart pigging technology has revolutionized pipeline inspection. Intelligent pigs equipped with magnetic flux leakage (MFL) inspection and ultrasonic testing provide detailed insights into pipeline conditions. These technologies help operators detect internal and external corrosion, metal loss, and other structural defects, ensuring compliance with industry regulations and standards.

Final Thoughts

Pipeline pigging plays a crucial role in maintaining the efficiency and safety of pipelines across industries. Whether using cleaning pigs, intelligent pigs, scraper pigs, or de-watering pigs, having the right pigging equipment ensures optimal pipeline performance. Implementing a well-designed pigging system with high-quality pig launchers and receivers will minimize downtime, reduce costs, and enhance pipeline integrity.

Regular pigging and inspection through smart pigging technology will keep pipelines functioning at their best while ensuring environmental and operational safety. If you’re looking for reliable pipeline pigging solutions, investing in high-quality pigging equipment is the key to long-term pipeline efficiency and performance.

Looking for Expert Guidance?

If you need assistance selecting the right pipeline pigs and pigging equipment, our team is here to help. Contact us today for professional insights and recommendations on optimizing your pipeline maintenance strategy!