K-60

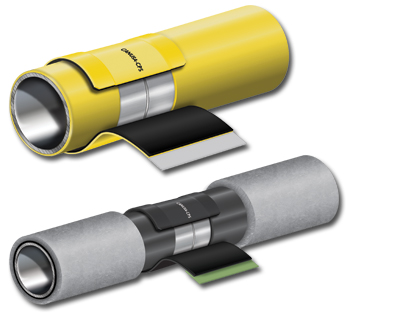

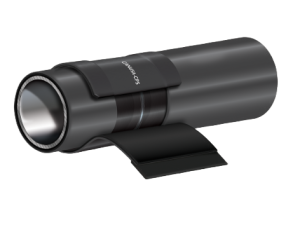

The Canusa K-60 wraparound sleeve is designed for corrosion protection of buried and exposed steel pipelines operating up to 60 C (140°°F). K-60 consists of a crosslinked polyolefin backing, coated with a technologically advanced corrosion protective adhesive, which effectively bonds to steel substrates and common pipeline coatings including polyethylene and fusion bonded epoxy.

Long Term Corrosion Protection

Canusa’s K-60 shrink sleeve provides excellent resistance to cathodic disbondment resulting in effective long term corrosion protection.

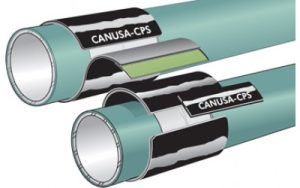

Once installed, the K-60 shrink sleeve provides the structural integrity of a seamless tube, and provides the substrate with durable protection against abrasion and chemical attack.

Rapid & Reliable:

K-60 has a patented one-piece Wrapid Sleeve™ construction that incorporates a pre-attached closure strip as part of the sleeve. Because the closure has been factory applied, quick and reliable field installation is easy to accomplish.

For added flexibility, CanusaWrap™ two-piece cut sleeves or bulk rolls are also available. K-60 is supplied with a yellow polyethylene backing for buried pipelines or a black backing with added UV resistance for above ground pipelines.

Saves Time & Money:

The Canusa K-60 shrink sleeve can be supplied with a pre-attached closure or in bulk roll / cut sheet format with a separate closure. This versatility provides contractors choice and conve-nience depending on the type of project.

For large projects, the unique construction of a pre-attached closure allows for quicker installation time versus handling, positioning and installing separate closures. For smaller projects or where multiple pipeline diameters are present, the convenience of bulk rolls or pre-cut sleeves with separate closures provides for maximum flexibility and minimizes inventory costs.