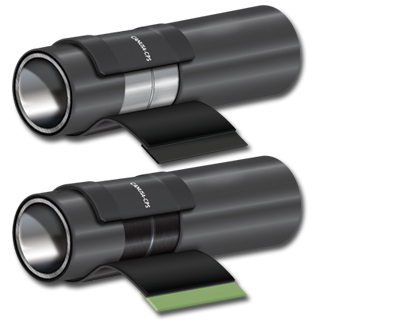

GTS-80

The GTS-80 system provides superior corrosion protection and excellent bonding on pipelines operating up to 80°C.

GTS-80 has been designed with a unique adhesive technology that remains “open” longer than traditional adhesives. Also, special surface active agents allow bonding to lower surface energy coatings (such as polypropylene). As a result, lower preheat temperatures are required to attain true adhesive wet-out and superior bonding to PE and FBE surfaces is achieved.

Superior Force Cured Epoxy

Proven method of force curing the liquid epoxy to the steel allows

the installer to “pre-inspect” the joint prior to sleeve application. Force cured epoxy cannot be displaced during the aligning and shrinking stages of the sleeve installation.

Unique Adhesive Technology

Allows for lower installation pre-heat temperatures and superior

bonding to PE and FBE coatings .Adhesive has been formulated to bond directly to the main line coating; epoxy is applied to the steel only.

Flexible Installation

For added flexibility, the sleeve can be supplied as bulk rolls or pre-cut to the required pipe size.

Long Term Corrosion Protection

Provides a protective coating with the structural integrity of a seamless tube, providing excellent resistance to cathodic disbondment and excellent durability against abrasion and chemical attack.

Saves Time & Money

Lower pre-heat means less time heating.