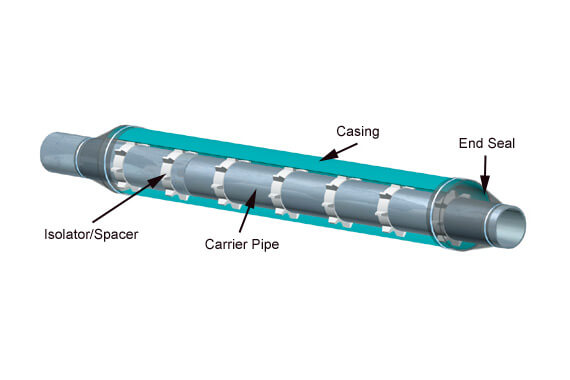

Model PE Non-Metallic Casing Spacers

High density (linear), injection molded virgin polyethylene casing isolators/spacers provide positive insulation, high abrasion resistance and low coefficient of friction for a wide variety of double containment carrier/casing pipe applications. They are extremely light in weight and easy to handle during installation.

A ribbed inner surface prevents slippage and guards against carrier pipe coating damage while the outer surface may include any one of several molded runners to accommodate 2″ (50.8mm) x 4″ (101.6mm) or larger carrier/casing differentials.

One piece solid molded segments provide for maximum load bearing. Hardware includes cadmium plated steel studs, nuts and washers. A screwdriver is the only tool needed for installation.

***For sale in Canada only, United States customers please contact your local distributor***

- For carrier pipe diameters (Nominal Steel & IPS) ranging from ¾” (19.1mm) to 48” (121.9cm).

- Spacing recommendation: Max 8’ (243.8cm) between spacers, Max 2’ (61.0cm) from casing pipe end.

- Recommended end seals: Model S, C, W, FW and R.

Hardware

Metallic – Bolts and Square Nuts = Plated Steel

Runners

| Model Size | Band Width | Runner Height |

|---|---|---|

| 3/4 x 2 | 3" | 5/16" |

| 1 x 3 | 3" | 1/2" |

| 1-1/4 x 3 | 3" | 1/2" |

| 1-1/2 x 3 | 3" | 1/2" |

| 2 x 4 | 4" | 5/8" |

| 2-1/2 x 5 | 4" | 5/8" |

| 3 x 6 | 4" | 5/8" |

| 4 x 6 | 4" | 9/16" |

| 4 x 8 | 4" | 1" |

| 6 x 8 | 4" | 9/16" |

| 6 x 10 | 4" | 1" |

| 8 x 10 | 4" | 9/16" |

| 8 x 12 | 5" | 1" |

| 10 x 14 | 5" | 7/8" |

| 12 x 16 | 5" | 7/8" |

| 4" differential segments | 6.25" | 1" |

| 6" differential segments | 6.25" | 1-1/2" |

- 5″ (127mm) wide band for maximum hoop strength around carrier pipe.

- Ribbed inner surface prevents slippage and guards against coating damage.

- Molded from virgin polyethylene material.

- Lightweight for ease of handling and installation.

- Screwdriver is only tool needed for installation.

- Model available with non-metallic hardware.

- High-temp model available (up to 12″ [305mm]) for service termperatures to 280-degrees F. (138-degrees C.).

- Eliminates the Need for Blown Sand or Pea Gravel