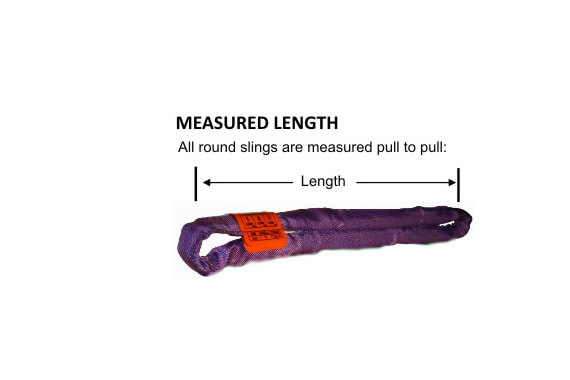

Polyester Round Slings

A polyester round sling, also referred to as a tubular sling is composed of a continuous load bearing core(s) made from synthetic polyester yarns, not woven, fully enclosed in a protective cover(s), with or without fitting(s) or coupling component(s) used for general lifting purposes.

Safety is the first concern in the use of any polyester round sling or any sling. The proper polyester round sling must be chosen for the job. Rigger should be trained & certified and must know the proper hitch to use; where and how to attach polyester round slings to the load. Therefore, riggers shall acquire the knowledge not only of the different type hitches but the way loads can be expected to react when the lift is made.

The slings are available in many different sizes and weight capacities.

Contact Order Desk

Round Sling Features

- The most flexible sling available.

- The round sling conforms to the load extremely well, and provides the best choker hold.

- Hook and load contact points can be continually rotated to extend the service lift of the round sling.

- Longer sling life means cost reduction in sling purchases.

- The load bearing fiber never comes into to contact with the load.

- Protection to the load from sling damage.

- Seamless cover, no edges to wear out.

- Wide variety of sling lengths and load capacities.

- Adapts to all types, sizes, and load configurations.

- Lightweight, easy to rig, store, and clean.

- Excellent resistance to ultra-violet light, rot and mildew.

- No loss of strength in water.

- Only 3% elongation on polyester rounds, and 1% on high-performance rounds.

- Maximum temperature exposure 194°F.

- No metal parts on the round sling to rust.

Round Sling Construction

Round slings are constructed from a multiple of high tenacity polyester yarns in an endless or continuous loop. These load bearing yarns are protected by two woven polyester jackets. The polyester jackets act a s a buffer between the load and the polyester yarn.