TBK-60

The Canusa Wrapid Sleeve™ Type TBK-60 is a onepiece wraparound sleeve designed for corrosion protection of buried and exposed steel pipelines operating up to 60 C (140 F).

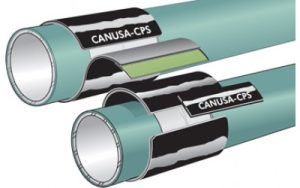

TBK-60 consists of a cross-linked polyolefin backing, coated with a technologically advanced protective adhesive which effectively bonds to steel substrates and common pipeline coatings including polyethylene and fusion bonded epoxy.

Canusa’s TBK – Directional Drilling Kit provides superior corrosion protection because of the protective combination. This primary sleeve provides excellent resistance to cathodic disbondment & excellent durability against abrasion and chemical attack . The result is effective , long term protection against corrosion.

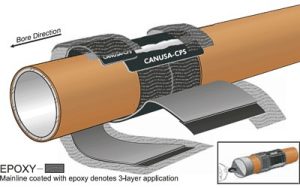

- Force-cured liquid epoxy applied to steel, if required, for maximum corrosion protection.

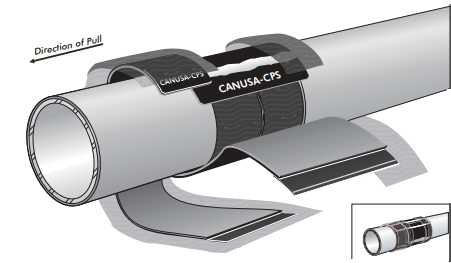

- Primary sleeve composed of high shear strength adhesive, a protective heat shrinkable backing, and a pre-attached closure patch.

- Sacrificial sleeve incorporated to protect the leading edge of the underlying primary sleeve during pull-through operation.

- Epoxy overcoat applied at the leading and trailing ends of the joint coating to provide additional protection to the system during directional drilling.

- Designed to mitigate the effect of forces associated with directional drilling.

- Highly resistant to the effect of soil stresses and pipe movements.

- Canusa’s ScarGuard®, WrapidShield PE and HBE-DX products are provided as alternatives for added mechanical protection as an overcoat.

- Allows for lower installation pre-heat temperatures and superior bonding to mainline coating.

- Adhesive has been formulated to bond directly to the mainline coating; epoxy (if required) is applied to the steel only.

- Lower pre-heat temperature means less time heating resulting in application time and cost.