TBK-80

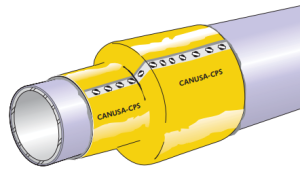

The Canusa Wrapid Sleeve™ Type TBK-80 is a wraparound sleeve designed for corrosion protection of buried and exposed steel pipelines operating up to 80 C (176 F).

The TBK Directional Drilling system is specifically designed to protect welded joints on PE, FBE and HPCC coated pipelines in directional drilling applications.

In addition to providing effective protection against pull-through forces that occur during the directional drilling operation, Canusa’s TBK systems provide superior corrosion protection at pipeline weld joints.

Multi-Layers of Protection

• Force-cured liquid epoxy applied to steel, if required, for maximum corrosion protection

• Primary sleeve composed of high shear strength adhesive, a protective heat shrinkable backing, and a pre-attached

closure patch

• Sacrificial sleeve incorporated to protect the leading edge of the underlying primary sleeve during pull-through operation

• Epoxy overcoat applied at the leading and trailing ends of the joint coating to provide additional protection to the system during directional drilling

Superior Gouge and Abrasion Resistance

• Designed to mitigate the effect of forces associated with directional drilling

• Highly resistant to the effect of soil stresses and pipe movements

• Canusa’s ScarGuard®, WrapidShield XLE and HBE-DX products are provided as alternatives for added mechanical protection as an overcoat

Unique Adhesive Technology

• Allows for lower installation pre-heat temperatures and superior bonding to mainline coating

• Adhesive has been formulated to bond directly to the mainline coating; epoxy (if required) is applied to the steel only

• Lower pre-heat temperature means less time heating resulting in application time and cost