As most of Canada gets ready for cooler temperatures and the arrival of winter, pipeline operators in core industries like oil & gas face the challenge of ensuring their equipment operates efficiently despite the dipping climate. Extreme cold, snow, and ice can damage machinery and hinder job site safety and productivity, and essential tools like pipe-bending machines need proper care to work their best all season long.

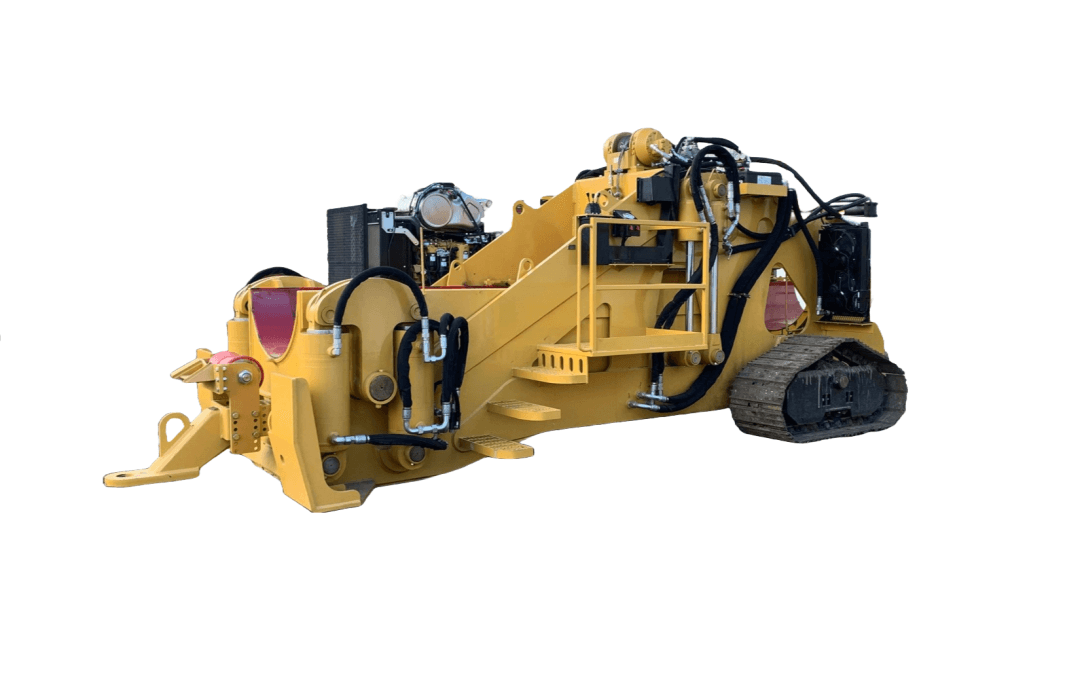

As one of Canada’s leading suppliers of pipeline tools, resources and machinery -including bending machines – Proline Pipe Equipment knows how important it is to stay on top of winter care for the best results. Below, we’ll discuss some of the best ways to help mitigate cold weather challenges, as well as the benefits of partnering with Proline for your pipeline needs. Read on to learn more!

Cold Weather Impact on Metal Properties

Winter’s freezing temperatures can be harsh on metal, even the tough alloys used in pipeline construction and maintenance. Prolonged exposure to subzero temperatures can leave pipes brittle and less malleable, increasing the risk of cracking or fractures during bending. Proline’s bending machines are engineered to handle heavy-duty projects and allow for more precise control over bending force and speed. This reduces the risk of damage to brittle pipes in cold weather conditions and allows operations to continue safely.

In extremely cold environments, preheating the pipes before bending is often necessary to restore ductility and prevent fractures. Even in difficult winter conditions, operators and maintenance personnel can rely on Proline’s manual bending equipment paired with our pre-heating tools to achieve precise bends, thanks to their durability and dependability.

Lubrication and Maintenance

Unsurprisingly, cold weather can be disastrous for lubrication systems and other mechanisms that rely on fluids for their operation. Lubricants often thicken or freeze in cooler temperatures, increasing friction and wear and tear on components. To avoid this, it is important to use cold-weather lubricants that are specifically formulated to retain their viscosity in freezing temperatures. Ensuring that all moving parts, like gears and rollers, are well-lubricated throughout winter can prevent damage to the machine and costly downtime.

Power and Hydraulic Systems

Harsh climate conditions can have a significant effect on the power and hydraulic systems of pipe-bending machines, especially on job sites where exposure is unavoidable and persistent. As with lubrication systems, hydraulic fluid thickens at lower temperatures, which lowers the efficiency of your unit and can even lead to complete failures if not properly maintained. Weather-graded fluid is crucial to maintaining proper flow and pressure, and hydraulic systems should be insulated and kept warm whenever possible. Pre-start checks, using heating pads on hydraulic tanks, and investing in insulating covers for vulnerable components help keep the risks associated with cold weather exposure to a minimum and should become routine practice during winter months.

Equipment Storage and Protection

Proper storage of pipe-bending machines (and all mechanical equipment) is critical during the winter months. Cold, wet conditions, such as freezing rain and snow, accelerate wear and tear, lead to corrosion, and can permanently damage sensitive components. Always store your machinery in an insulated or heated environment to avoid these hindrances. For job sites where it is not possible to store your unit inside, use weatherproof tarps to cover your machines and minimize their exposure to harsh elements.

Operator Safety

Finally, winterizing your pipe-bending machines isn’t just about protecting the units themselves. It’s just as important to ensure that operators are prepared to deal with different seasonal conditions and avoid the risk of accidents and injury that accompany the cold, slippery winter weather. Make sure all crew members are equipped with adequate clothing, including insulated gloves, non-slip boots and eye protection, as well as trained on any winter-specific protocols (for example, knowing to preheat piping before bending) to ensure maximum efficiency and avoid unnecessary risks on the job site.

Stay Efficient All Year Round With Proline Pipe Equipment

Winter conditions pose unique challenges for pipeline construction, particularly when operating pipe-bending machines. Fortunately, with a little forethought and preparation, as well as the right equipment from a trusted supplier like Proline, you can help your equipment operate at its best, even in extreme winter conditions.

With decades of industry-leading experience, a robust product line that stands up to tough conditions, and 24/7 support you can trust. Proline is here to help your operations run smoothly all year round. View our pipe-bending machines here and learn more by contacting our team today!