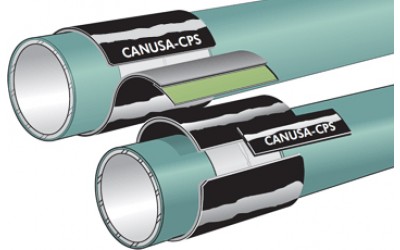

GTS-HT

GTS-HT sleeves consist of a thick crosslinked backing coated with a very high shear strength hot-melt adhesive. During installation the adhesive melts and flows, filling surface irregularities, and providing an excellent bond to metal and FBE coating.

The GTS-HT system provides superior corrosion protection and excellent bonding on FBE coated pipelines operating at temperatures up to 120°C (248°F).