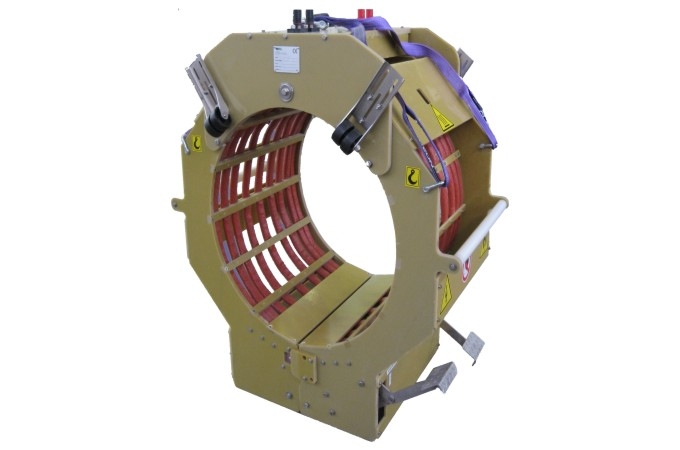

Heating Coils

Induction heating clamp coils are designed for coating and heating processes. These coils prepare the pipe’s steel surface for two main corrosion protection methods: heat-shrinkable sleeves (HSS) made of polyethylene or polypropylene, and Fusion Bonded Epoxy (FBE).

The coils provide uniform and consistent heating across the entire surface to ensure the proper application of the anticorrosive product. The main fiberglass structure ensures the durability required for field equipment and provides complete electrical insulation for operator safety. All other components, including the opening and closing mechanisms, levers, shafts, bolts, and other metal parts, are made of stainless steel. Electrical conductors are protected by high-temperature-resistant sleeves, and all electrically charged parts are securely sealed.

The standard opening and closing system is manual and available in two configurations: hand-operated (standard) or foot-operated (optional).

Clamp coils are designed based on thermodynamic simulations that simultaneously display the heat profile on the joint section and the progressive heat dissipation after the heating process stops.

Input Power: 120 – 150 kW

MAX Output Power: 120 – 150 kW

Frequency: 480 Hz

Duty Cycle: S3 – 50% (refer to duty cycle of generator)

Application: HSS – FBE – PWHT

Operating Temperature: -40°C to 60°C

Materials

Structure: Fiberglass G40

Mechanicals: AISI

Turns & Contact: Copper

Protection: Fiberglass Sleeve

Fast Connector: Powerlock – Gifas – Leviton

Cooling System: Air (water for special applications)