Description

Round Sling Features

- The most flexible sling available.

- The round sling conforms to the load extremely well, and provides the best choker hold.

- Hook and load contact points can be continually rotated to extend the service lift of the round sling.

- Longer sling life means cost reduction in sling purchases.

- The load bearing fibre never comes into to contact with the load.

- Protection to the load from sling damage.

- Seamless cover, no edges to wear out.

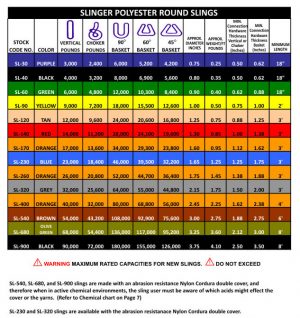

- Wide variety of sling lengths and load capacities.

- Adapts to all types, sizes, and load configurations.

- Lightweight, easy to rig, store, and clean.

- Excellent resistance to ultra-violet light, rot and mildew.

- No loss of strength in water.

- Only 3% elongation on polyester rounds, and 1% on high-performance rounds.

- Maximum temperature exposure 194°F.

- No metal parts on the round sling to rust.

Round Sling Construction

Round slings are constructed from a multiple of high tenacity polyester yarns in an endless or continuous loop. These load bearing yarns are protected by two woven polyester jackets. The polyester jackets act a s a buffer between the load and the polyester yarn.

Technical & Usage Information

Polyester Round slings

A polyester round sling, also referred to as a tubular sling is composed of a continuous load bearing core(s) made from synthetic polyester yarns, not woven, fully enclosed in a protective cover(s), with or without fitting(s) or coupling component(s) used for general lifting purposes.

Safety is the first concern in the use of any polyester round sling or any sling. The proper polyester round sling must be chosen for the job. Rigger should be trained & certified and must know the proper hitch to use; where and how to attach polyester round slings to the load. Therefore, riggers shall acquire the knowledge not only of the different type hitches but the way loads can be expected to react when the lift is made.

Polyester Round Sling Identification

EACH POLYESTER ROUND SLING SHALL BE DURABLY MARKED OR LABELED SHOWING:

1. Name or trademark or manufacturer.

2. Manufacturer’s code or stock number.

3. Rated capacities (vertical, choker, vertical basket).

4. Polyester core – if cover(s) is of a different fiber type, both fiber types shall be identified.

5. Sling identification has to be maintained by the user so it can be legible during the life of the sling.

6. Length.

RECOMMENDED OPERATING PRACTICES

Mechanical Considerations

Polyester round slings shall always be protected from being cut by corners, edges and protrusions. Wear pads are available for each specific job.

Determine the weight of the load. Polyester round slings shall not be loaded in excess of their rated capacity. Consideration shall be given to the angle from the horizontal (round sling to load angle) which affected rated calamities.

Select a proper polyester round sling having suitable characteristics for the type of load, hitch and environment.

Polyester round slings with fittings that are used in a choker hitch shall be of sufficient length to assure that the choking action is on the polyester round sling and never on the fitting.

Polyester round slings used in a basket hitch shall have the load balanced to prevent slippage

Do not twist or tie into knots, or joined by knotting and slings should not be pulled from under loads when the load is resting on the sling.

Polyester round slings shall be used with lifting devices that are compatible with round slings.

Do not drop polyester round slings equipped with metal fittings.

The opening in fittings shall be the proper shape and size to ensure that the fitting will seat properly on the polyester round sling, crane hook or other attachments.

Polyester round slings protective covers that are cut exposing the load bearing yarn should be disposed and removed from service.

Consideration shall be given to the fitting’s radius in that it shall be compatible to that of the crane hook on which it is to be used.

Consideration shall be given to the distribution of load weight on a multi-legged lift.

Environmental Considerations

When not in use, polyester round slings should be stored in a cool, dry and dark place to prevent loss of strength from exposure to ultra-violet rays.

Chemically active environments can affect the strength of polyester round slings in varying degrees ranging from little to total degradation. The polyester round sling manufacturer, or qualified person, should be consulted before round slings are used in a chemically active environment.

Acid

1. Polyester is resistant to some acids, but is subject to degradation ranging from little to moderate in some acids.

2. Each application shall be evaluated, taking into consideration the following:

a. type of acid

b. exposure conditions

Alkalies

1. Polyester is subject to degradation in alkalies ranging from little to total degradation.

2. Each application shall be evaluated, taking into consideration the following:

a. type of alkali

b. exposure conditions

Polyester round slings shall not be used at temperatures in excess of 194 degrees F (90C), or at temperatures below minus 40 degrees F (-40C).

Polyester round slings incorporating aluminum fittings shall not be used where fumes, vapors, sprays, mists or liquids of alkalies and/or acids are present, unless the compatibility of these materials is verified by the manufacturer or a qualified person.