Description

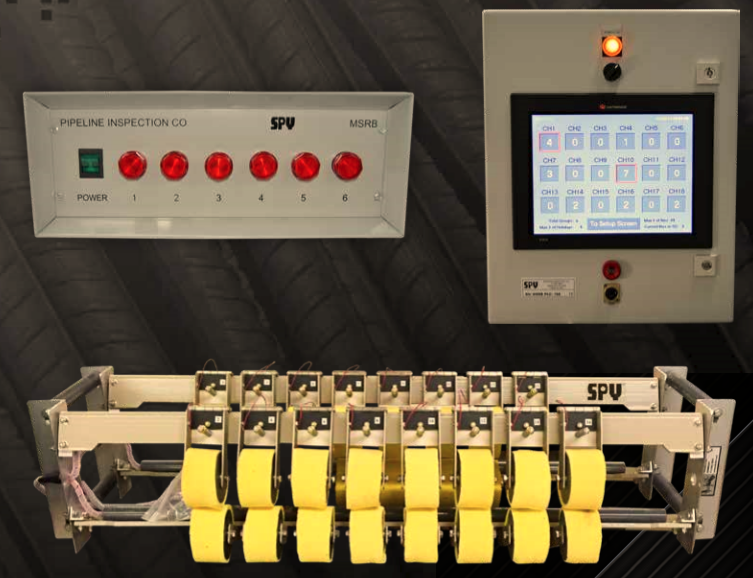

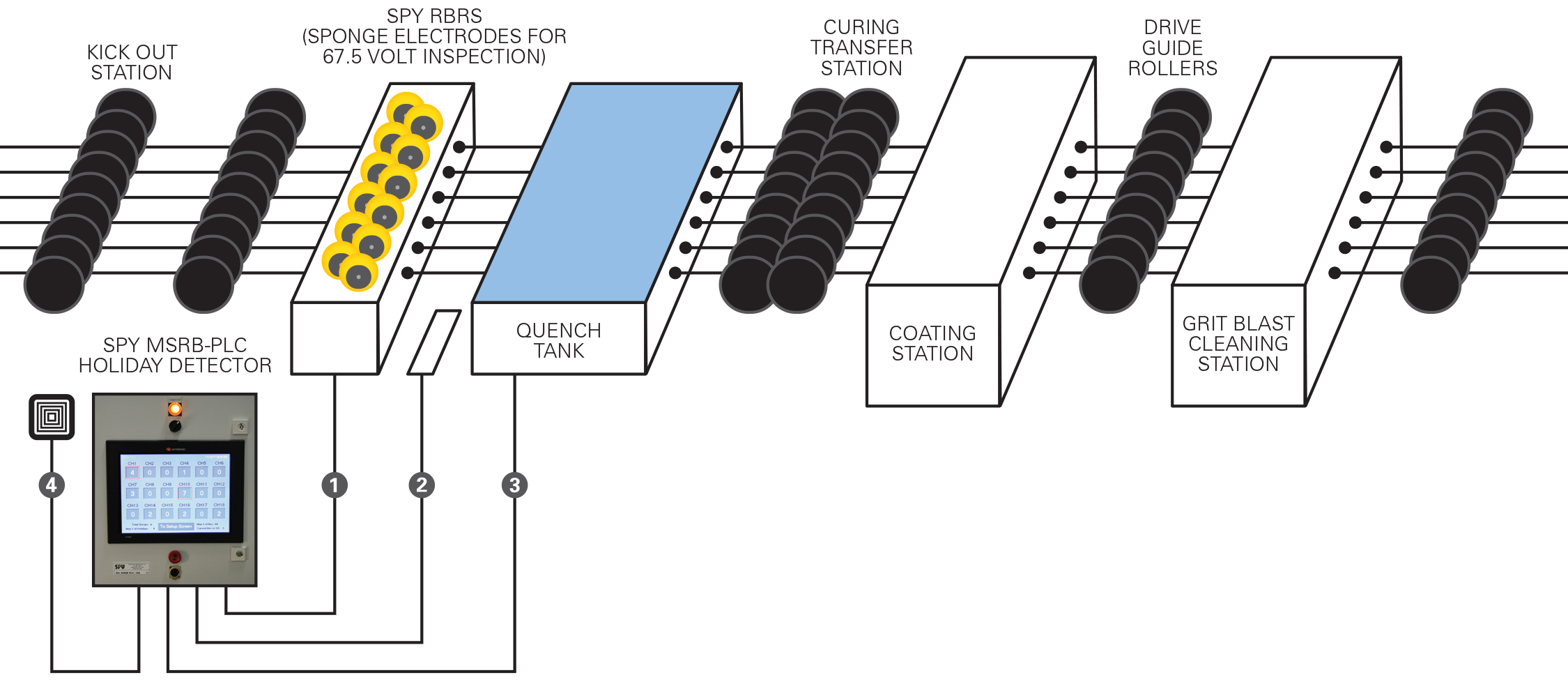

Installed on a reinforcing bar (rebar) coating line, the SPY® MSRB system continuously monitors the coating as the rebar runs through the RBRS dual roller wet sponge electrodes unit. When a discontinuity in the coating (holiday) is discovered, a red light at the appropriate station on the detector unit flashes to give a visual indication. The detector unit gives an electrical output to a plug on the back of the unit. Any 120 volt AC customer furnished horn, bell, recorder, computer, etc. can be driven from the MSRB switch signal output plugs.

THE MSRB-PLC REBAR HOLIDAY DETECTION SYSTEM uses an inductive sensor to sense the approach of a freshly coated rebar batch. The rebar exits the cooling process which then activates the MSRB-PLC Holiday Detection System to prepare for the rebar batch to pass through our dual-roller wet sponge electrodes (RBRS). Moisture from the sponge electrodes conducts a low inspection voltage (67 Volts) to the coating of each coated rebar. This allows the MSRB-PLC System to detect any holiday (defect) in the rebar coating.

TECHNICAL FEATURES

Voltage Type: DC

Voltage Range (kV): 67.5 Volts

Voltage Output Accuracy: ±5%

Coating Range (Min-Max): 1 – 20 mils

Operating Temperature: -40°F to 148°F

Display Type: LCD

Holiday Indicator Type: Visual / (Optional) Audio

Power Requirement: 120V AC (Optional 220V – 120V transformer)

Unit Weight (lb): 20 lbs

Unit Dimensions (LxWxH): 15.75” x 20” x 9”

Domestic/International Standards Unit Complies With: NACE SP0188-2006

Factory Warranty: 12 Month

PRODUCT FREATURES

- Certified Enclosure

- Digital Holiday Channel / Unit Operation Display

- Individual Channel Holiday Indicator Lights (Optional)

- Audible Holiday Horn

- Ethernet Connector

PROLINE PIPE EQUIPMENT INC. IS A FACTORY AUTHOURIZED REPAIR FACILITY